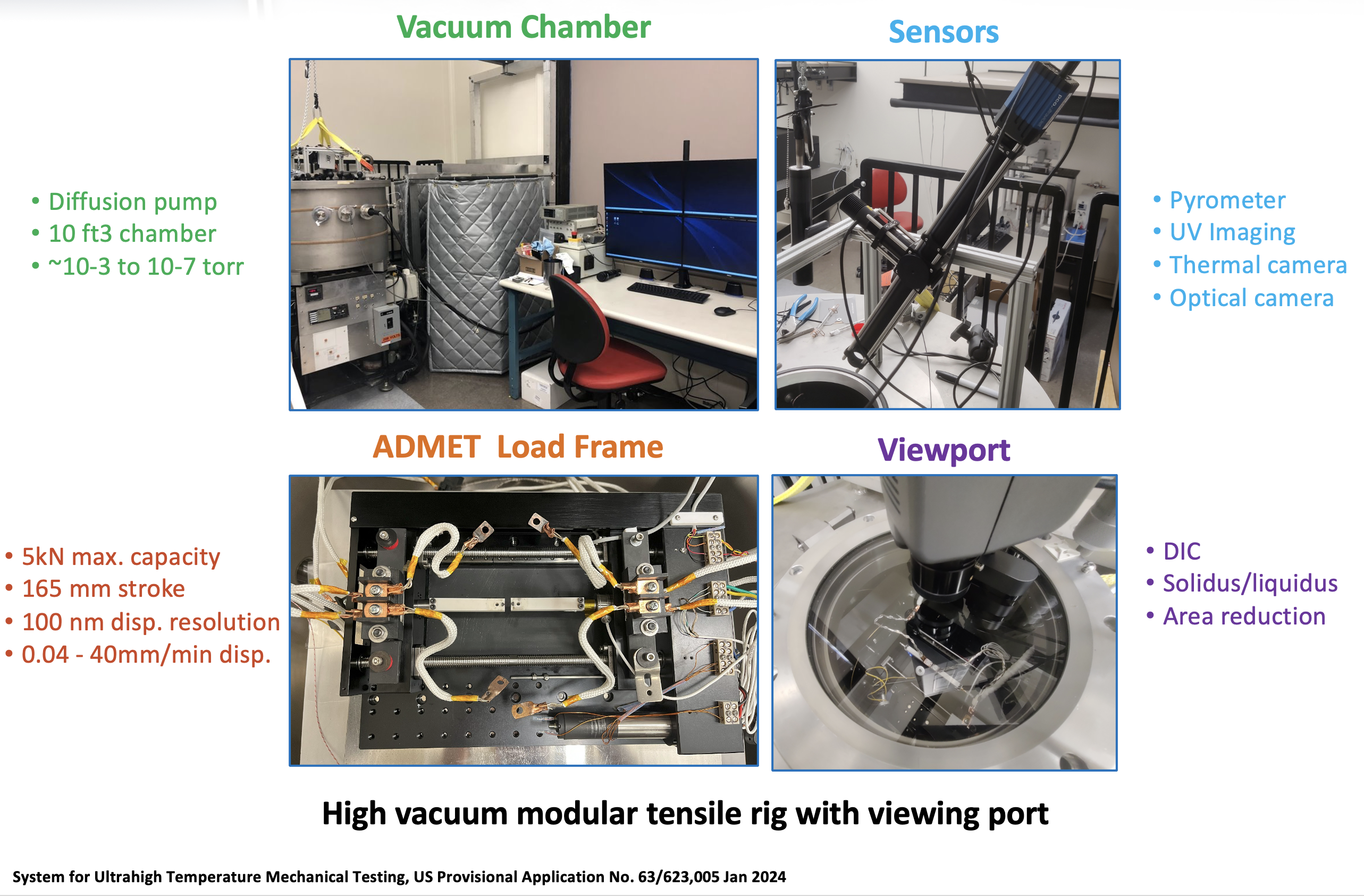

Ultra High Temperature (UHT) Tensile Tester

36” diameter chamber which that houses a custom ADMET load frame capable of performing tension, compression, and stress relaxation tests. Tests can be run either stroke-controlled, load-controlled, or a combination. The current load cell is capable of reaching loads of 5 kN. The system is able to reach vacuums down to 10-7 Torr and temperatures ~2000 °C. Both a multi-spectral pyrometer and a FLIR thermal camera can be used to monitor temperature. Possible measurements include yield strength, UTS, Young’s modulus, emissivity, melting temperature (or solidus/liquidus), and CTE. UV DIC for local strain measurements is in development.

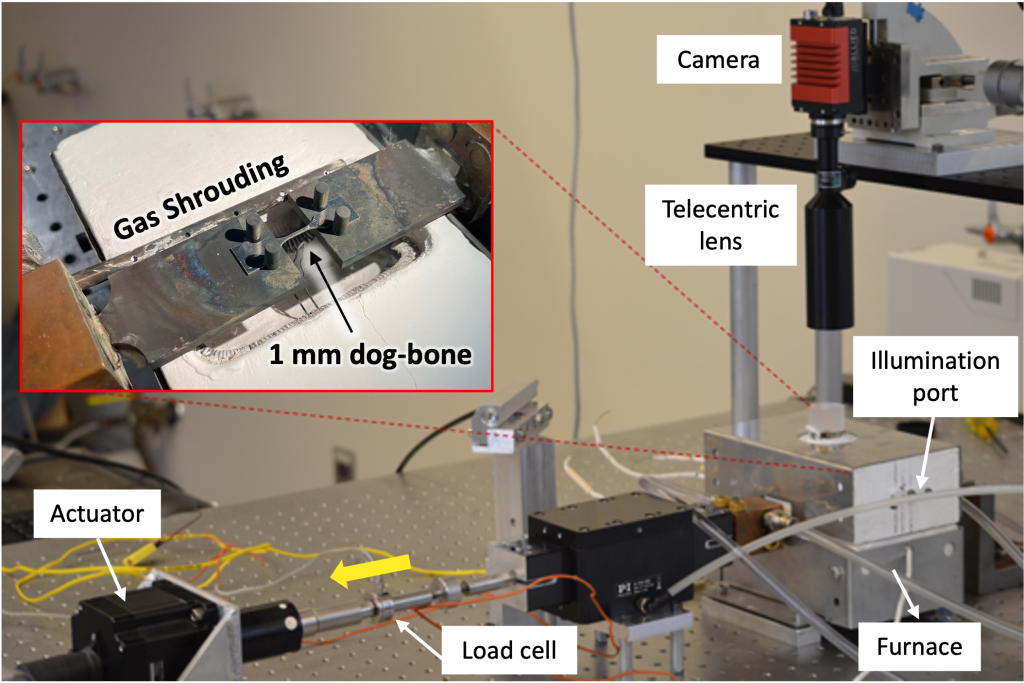

Milli-High Temperature Tensile Testing (Milli-HTTT) Setup

This setup is a stroke-controlled tensile tester with a 1200 N load cell for millimeter scale samples. It can be used to carry out tests at room temperature as well as elevated temperatures up to 1100°C. It is equipped with a gas shrouding system allowing tests to be done in inert environments (argon or forming gas). The polished quartz rod in the furnace lid allows in-situ DIC to be run during high-temperature tests.

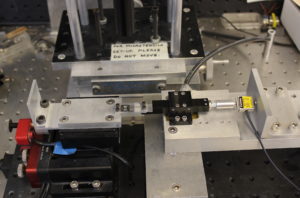

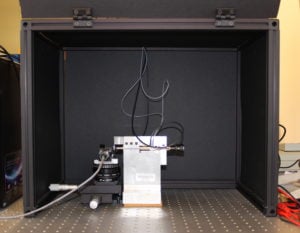

Thin Film Microtensile Setup

Small load frame for very thin film tensile testing combined with DIC for strain measurements. Load cells 2.5 and 0.1N available.

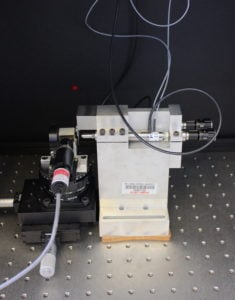

Micro-High Temperature Tensile Testing (Micro-HTTT ) Setup

A compact furnace and load frame experimental setup for testing mechanical properties of microscale samples at elevated temperatures. The load frame features ceramic grips that allow for testing at temperatures up to 1100°C and can be configured for testing microtensile samples as well as 3 and 4 point bending samples. The high temperature load capacity is 110 N.

Coefficient of Thermal Expansion Testing (CTE) Setup

Non-contact technique to measure in-plane CTE as a function of temperature. Field of view roughly 2mm x 3mm with a maximum furnace temperature of 1100°C.

Microbending Fatigue Setup

Unique specimen geometry with fatigue loading via pure bending, torsion or a combination of both. Specimen is driven in resonant frequency, which is monitored to establish damage accumulation.

Vacuum Tube Furnace

The vacuum tube furnace consists of a quartz tube with ID of 46mm and length of 36” to temperatures up to 1100°C. The quartz tube can be put under high vacuum or backfilled with a chosen gas. The furnace can be quickly rolled on and off the tube to allow to faster heating and cooling rates.

MTS Load Frame

Large MTS load frame capable of 100 kN or 500 kN maximums. Various grips including tension vice grips and compression platens are available.

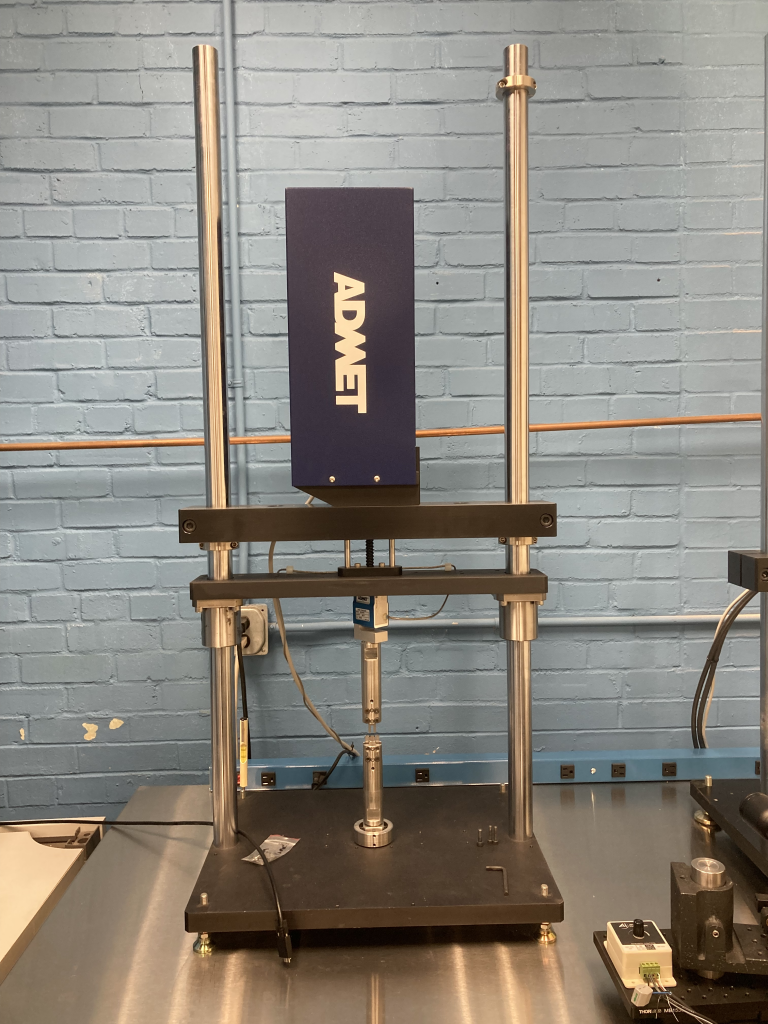

Admet Quasistatic Load Frame

This ADMET eXpert 5600 Series tensile tester has a maximum crosshead velocity of 0.8 mm/s, ideal for quasistatic tests. It has load capacity of 2.2 kN.

Admet Fatigue Load Frame

This ADMET eXpert 4900 Series has a maximum crosshead velocity of 21.2 mm/s, more suitable for fatigue tests. It can perform fatigue tests at rates up to 15 Hz. It has a maximum load capacity of 1.5 kN and can accommodate samples thickness between 0.2 to 2.0 mm.

Polisher

The automated polisher is used with a hand-held tripod mount for both small samples preparation and TEM wedge specimens. Various silicon carbide grit papers, diamond grit papers and various colloidal solutions can be used for sample surface preparation.

Optical Microscope

The optical microscope has a computer interface to capture the magnified images and do quick annotations. Magnifications include 5, 10, 20 and 50x objective lenses.

General Facility Contacts

To report active building emergencies (floods, leaks, electrical hazards, etc), the FIRST line of defense should be:

JHU Customer Service @ Plant Operations

410-516-8063

Monday – Friday 8 am – 5 pm

For after-hours facilities emergencies, or public safety issues, please contact the following:

Campus Security

41-516-4600